The project

Starchy baby foods are among the first nutritious choices of semi-solid food for babies. However, as the digestive system of infants is not fully developed, the consumption of starchy foods results in reduced energy intake and the appearance of digestive dysfunctions. The new trend in technological research, concerning starchy baby foods, is the controlled partial pre-hydrolysis of starch by enzyme mixtures (amylases). This process is expected to make baby foods more digestible for infants, reduce viscosity and increase the energy and nutrients absorption by infants as well as the sweetness of the final product. The enzymes, currently available for use for the above process, are not suitable as their activity is not familiar to the cereal starch used in baby food (rice, oats, wheat, etc.). In addition, they are not completely deactivated after their use, as a result of which the hydrolysis continues uncontrollably, directly affecting the rheological characteristics (high viscosity reduction) of the product. Based on the above, and with the aim of solving this technological problem, in this project YIOTIS S.A. will collaborate with two academic partners to develop amylase mixtures specialized for use in baby food flours, which will be completely safe for consumption by infants and will be derived from psychrophilic microorganisms so that they are completely inactivated at low temperatures.

The main objective of COLDZYME is the development, production, and evaluation of "tailor-made" mixtures of psychrophilic amylases for the pre-hydrolysis of starch in flour used for baby foods by YIOTIS S.A.. The amylolytic enzymes will be evaluated in terms of their activity in rice flour substrates that the company uses for its products, as well as their effect on the desired rheological and organoleptic characteristics of the final product.

The individual objectives of th project are therefore elaborated as follows:

With the completion of COLDZYME, the partner YIOTIS S.A. will have at its disposal a set of enzymes fully evaluated in terms of kinetics, stability, production processes, and integration into the company's production process, suitable for the immediate development of innovative pre-hydrolyzed baby foods.

Initially, the full evaluation and characterization of a group of psychrophilic amylolytic enzyme systems will be carried out, where genomes of microorganisms isolated from psychrophilic environments, such as species of the genera Bacillus, Arthrobacter, Bifidobacterium, etc., will be used as their sources. The enzymes will be fully studied in terms of their physicochemical characteristics and kinetic activity and they will be produced using laboratory bioreactors in quantities suitable for pilot tests. The ultimate goal is the development of an optimized mixture of amylases for the starch substrate, which, apart from the desired characteristics it will bring to the final product, will show zero activity, both during the subsequent stages of the production process, and during food preparation by the final consumer. The nutritional profile of the recipes with hydrolyzed starch will be evaluated, while at the same time a comparison will be made with competitive products.

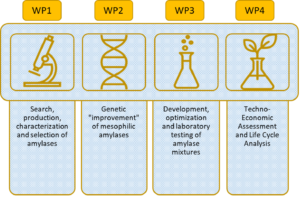

The project is carried out in 4 work packages (WP):

More specifically, in WP1, analysis of genomes and metagenomes from psychrophilic regions will be carried out, as well as identification of psychrophilic α-, β-amylases and isoamylases with a desired kinetic profile. The selected enzymes will be studied in terms of their physicochemical characteristics, the kinetics of their activity on natural starchy substrates, as well as the profile of the oligosaccharides produced through HPLC, HPLC MS/MS and NMR.

In WP2, a bioinformatic analysis will be made for the selected amylases of mesophilic microorganisms, with the aim of identifying amino acids that could reduce the thermostability of each enzyme with as little effect on its kinetic properties as possible. Targeted mutagenesis and cloning of the relevant enzymes will be applied in E. coli cells where the corresponding modified amylases will be biochemically and kinetically characterized

In WP3, the activity of the selected enzymes on "real" baby food starch substrates will be studied and it will be evaluated in mixtures of 2 or 3 activities, in various proportions between them. In bioreactor systems, the scale-up and optimization of enzyme production from the producing modified strain, as well as the modeling of the process, will be attempted. In addition, pilot production of a series of final products will be carried out with the addition of the evaluated enzyme mixtures.

In WP4 a techno-economic study will be carried out in order to calculate the cost per unit mass of final enzyme product. The viability of the proposed process and the fund required to scale up enzyme production will be assessed. The life cycle analysis of the entire production process of the products and the process will take place.

Upon completion of the planned work, a documented and state-of-the-art assessment of the economic applicability of psychrophilic amylase mixtures used in pre-hydrolyzed baby food will result.

Additional results of the project are:

- The possibility of applying for the first time the technology by YIOTIS S.A., will strengthen its position as a pioneer in baby food development, strengthen its competitive position in the Greek market and give new impetus to its efforts to penetrate new markets of abroad.

- The upgrade and establishment of participating research bodies as centers of excellence in new technologies development in the field of enzyme evaluation and production for the Food Industry.

- The creation of research collaborations with academic institutions, but mainly with food industries in the field of enzymatic and microbial modification of raw materials and other products, as well as with biocatalysts (enzymes) synthesis and production industries.

- The promotion of the Greek baby food industry as a vehicle for the development of new technologies and not only for the application of technology from abroad.

- The possibility of application to other Branches of the Food Industry with a significant effect on increasing its competitiveness.

- The employment increase, especially for young scientists of a high academic level, making the project a countervailing factor in the brain drain phenomenon of young scientists abroad. Within the framework of the project, the creation of 4 new jobs for specialized scientists is foreseen.

- The further activation of the participating research bodies (NKUA, NHRF) in publications in international scientific journals & announcements in Conferences, recruitment of new researchers, implementation of doctoral theses, and their collaboration with the Food Industry.